What’s Rotary Hammers

A rotary hammer is a power tool primarily used for drilling and grooving in hard materials such as concrete. It works by using high-speed rotation and impact force to easily penetrate hard materials such as concrete and stone. The impact force of a power rotary hammer is much greater than that of an electric drill. Handheld rotary hammers are generally divided into two types: one is for lighter work, usually using the SDS-plus chuck system, suitable for basic renovation work, such as installing conduits; the other is for heavy work, using the SDS-max chuck system, commonly used for drilling larger holes and long-term continuous chiseling work.

What’s Demolition Hammers

Unlike rotary hammers, demolition hammers have only a single impact function. They are power tools specifically designed for breaking, demolishing, and chiseling building materials. They are the power tools with the highest impact energy of all, and the higher the impact force, the higher the efficiency. Demolition hammers typically use HEX and SDS-max chuck systems for heavy-duty work, and different chisel bits are installed to accomplish different crushing tasks. Because of their high impact force, most demolition hammers are designed with shock absorption systems to protect your wrists and minimize vibration during use.

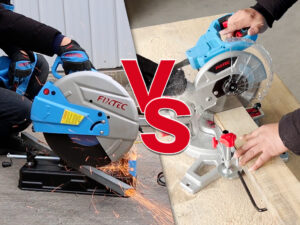

Which One to Choose:Rotary Hammer or Demolition Hammer

Power

You can compare their direct power in two ways: power and energy impact. Standard model rotary hammers typically have a power output of 500-800W, while heavy-duty rotary hammers typically have a power output of 1000-1500W. Rotary hammers have two functions: the motor power needs to support both the rotation and impact systems separately. The power is split, providing a stable and continuous impact during use. Demolition hammers have higher power, typically above 1000-2000W. Their power is more concentrated to support the impact function, helping you to continuously complete high-load demolition tasks.

Impact energy is another key factor that distinguishes the two power tools, measured in joules (J). Rotary hammers have relatively low impact energy, typically between 2J and 10J. Although its impact energy may seem small, its impact frequency is very high, enough to help you break concrete particles and complete drilling and light chisel tasks. Demolition hammers typically have high impact energy, ranging from 15J to 40J, with some heavy-duty demolition hammers exceeding 50J. This high-energy design aims to break hard materials more quickly, maximizing impact force and helping you complete heavy demolition work. Higher impact energy means higher work efficiency.

Applications

If you want to drill holes in concrete or brick walls, you will find that some drills are insufficient for these projects. A rotary hammer is necessary in this situation. Its SDS-plus bit with impact function works especially well on solid walls, creating quick and precise holes. It is far more effective to use it to drill holes and fix them for jobs like installing air conditioner brackets and electrical boxes. Additionally, it serves as a chisel, which makes it simple to carve shallow holes in the wall to conceal water lines or electrical conduits. It is lightweight and simple to use, but it cannot compete with a huge demolition hammer for wall demolition. A rotary hammer is a very practical option for small restorations and basic wall chiseling.

A demolition hammer should be used instead of a rotary hammer when working with hard materials that need to be extensively broken and demolished, like walls or concrete pavement. Its purpose is to swiftly break down big constructions, rapidly finish heavy-duty crushing tasks, and make cleanup easier. A heavy-duty demolition hammer like the SDS-max system is advised for more difficult professional chiseling tasks (such those requiring deeper ditches). You can perform deep chiseling operations more steadily and easily thanks to its strong single-impact energy.

Working Precision

Rotary hammers are high-precision construction tools. Taking their drilling function as an example, they can stably complete drilling work by simply applying a little force through the rotation of the drill bit. The depth gauge design of the rotary hammer drill helps you to precisely measure drilling depth, and the side handle design helps you easily maintain a stable drilling angle. It doesn’t have the same impact and destructive power as demolition hammers, leaving a complete drill hole without damaging the surrounding structure.

If your work doesn’t require high precision, and you only need to break parts quickly and efficiently without strict requirements on size and shape, then demolition hammers are your preferred tool. Demolition hammers are mainly used for repeated impact work. The violent impacts will increase the instability of the machine. This requires you to hold the handles on both sides firmly when using it. You have to rely entirely on your strength to control the chisel of the demolition hammer and prevent the tool from swaying from side to side. Meanwhile, the auxiliary handle of the demolition hammers is not designed to help you ensure work accuracy, but rather to have a shock-absorbing function to prevent it from slipping out of your hand during use.

Cost

Demolition hammers are more expensive than rotary hammers. If you have a limited budget and low usage requirements, you can start by wholesaling rotary hammers. Rotary hammers are also divided into entry-level and professional heavy-duty models. The professional models are more expensive than the entry-level models. It is recommended to try wholesaling different models to meet the different work needs of customers. Its drill bit accessories like sds-plus are also cheaper than demolition hammer drill bits, and the drill bit consumption rate is also lower.

Conversely, if your budget allows and there are many customers in the local renovation and construction industry, and construction companies or similar businesses in the vicinity have business needs, then wholesaling demolition hammers might be a viable option. Its more powerful motor, external structural design, and shock absorption system will result in a higher price.

Conclusion

Based on the above comparison, we can conclude that although both rotary hammers and demolition hammers are very suitable for concrete work, they differ in their division of labor: rotary hammers are responsible for precise drilling, while demolition hammers are responsible for efficient concrete removal. Hopefully, this blog can help you make more accurate investment decisions regarding rotary hammers and provide your clients with efficient and professional solutions. If you have any questions about other tools, please feel free to discuss them with us.

As a professional power tool supplier, FIXTEC Tools offers a wide range of rotary hammers and demolition hammers, including corded rotary hammers, cordless rotary hammers, brushless rotary hammers and jack hammers, to meet diverse customer needs. Whether you’re using lightweight models for drilling in wood, concrete, and steel, or heavy-duty rotary hammers for complex, continuous chisel and drilling work, we can provide a variety of drilling solutions. Our demolition hammers feature all-copper motors, 360-degree auxiliary handles, and an AVC (Anti-Vibration Control) system to help you provide stable and precise work. Some models also come with a portable BMC box and wheel barrow for easy handling. For bulk purchases of our rotary hammers tool series, we can provide certifications including CE, GS, RoHS, UL, and ETL to ensure product quality. We also offer OEM services. FIXTEC’s professional design team can create custom tool shapes, colors, packaging, and your brand logo to help you stand out in the market. We look forward to more wholesalers, importers, brand owners, and e-commerce sellers joining us.