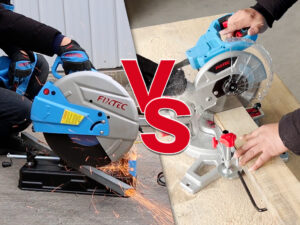

Mitre Saws Overview

As a precision cutting power tool, the miter saw makes miter cuts by rotating the saw blade left and right. By beveling, the cutting angle can be precisely set to meet the needs of splicing, decoration, or structural assembly. Therefore, you will find that miter saws are very suitable for furniture manufacturing, building decoration and other fields. To further improve cutting accuracy, some advanced miter saws are also equipped with laser positioning to help you align the cutting position.

There are two other common types of miter saws on the market: compound miter saws and sliding miter saws. The compound miter saw is an upgraded version of the miter saw. Its saw head can cut at an angle to the left, thus achieving both bevel cuts and angled cuts. A sliding miter saw is a compound mitre saw equipped with a sliding guide rail, which can move back and forth to perform cutting work, helping you to increase the cutting width.

Chop Saws Overview

A chop saw is a type of electric saw commonly used for cutting straight lines. It uses a special metal saw blade or abrasive wheel blade to quickly cut hard materials such as metal, and is widely used in construction, metal processing, and industrial fields. The chop saw has a simple structure, with a chop saw on top and a fixed base below. It does not have a complicated design that allows for angle adjustment, but it has high power and fast cutting speed. If you are using a cutting saw without sufficient experience, it is recommended that you wear protective gear to protect yourself.

Mitre Saw vs Chop Saw: Find Differences

Function

Compared to a chop saw, a miter saw has a more complex structure and therefore offers a wider range of cutting options: it can precisely perform cross cuts, miter cuts, bevel cuts and compound cuts. The main feature of a miter saw is its precision machining capability, allowing for angle cuts from 0 to 45 degrees. Its bottom features a round table with a miter scale to help you make precise cut adjustments. Mitre saws are ideal for making picture frames, installing flooring, decorative moldings, and other jobs that require precision shaping and splicing.

The chop saw has a relatively simple function; its blade can only move vertically up and down, and it can only cut straight lines. Just like its name, chop, it cuts through objects like an axe, which requires it to be very fast to cut. Therefore, you will find many chop saws on the power saws market equipped with motors of different power, generally above 2000W. The chop saw’s single straight-line cutting function is more suitable for beginners, helping you to cut materials quickly and in large quantities. However, compared to the mitre saw, its cutting precision is weaker, and the cut surface may be rough.

Cutting Material

The mitre saw can be used to cut wood and plastic, but it is best suited for cutting wood. With its precise cutting, multi-angle cuts, and smooth cutting surface, the mitre saw is an essential power tool for many professional woodworkers. You only need one mitre saw to complete a variety of woodworking tasks, helping you improve your work efficiency. As long as you use a saw blade with different gears, the mitre saw can cut different kinds of wood, such as softwoods like pine, hardwoods like oak and maple, and some plywood.

A chop saw can be used to cut various metals, stone, and pipes, but it is best suited for cutting metals. Whether it’s steel pipes, aluminum alloys, iron, or other metals, it can complete the cutting operation efficiently and quickly, making it a common tool in metalworking shops.

Blade Types

Different types of power saws require different saw blades when cutting different materials. For example, when cutting wood with a mitre saw, carbon alloy toothed saw blades are commonly used. These blades are harder, more wear-resistant, and suitable for various chainsaw applications. If you need to cut hardwood, you should choose a high-tooth count (80-100 teeth) saw blade, which will produce a smooth cut. If you want to cut softwood, you should choose a low-tooth count (24-40 teeth) saw blade, which will ensure a fast cut, but the cut surface will be slightly rougher.

Taking chop saw cutting metal as an example: resin abrasive wheel saw blades are mostly used. Even when the chop saw is cutting metal at high speed, the resin abrasive wheel saw blades will not have teeth or meshing. They can provide power and stable cutting performance for chop saws.

Portability

To enable cutting at various angles, the mitre saw features a base equipped with a mitre table, mitre scale, and side support bars, all designed for precision cutting, these designs make the mitre saw heavier and larger. If it’ s a sliding mitre saw, the weight of the sliding rail will be added. Not to mention that mitre saw themselves are made with metal casings to adapt to industrial working environments.

Chop saws are relatively lightweight and easy to move around. They lack other cutting aids and have a compact overall structure; even with a saw blade, they can be moved by simply gripping the base and chop saw handle.

Budget

If you want to wholesale mitre saws, you’ll need a sufficient budget. The mitre saw’s versatile cutting design makes it slightly more expensive, but from a long-term perspective, it’s a worthwhile investment. Many professional carpenters prefer to buy mitre saws to meet the needs of different woodworking tasks. They not only help them complete delicate woodworking work and reduce wood waste, but also improve work efficiency, making it a more cost-effective option for them. However, you also need to consider the budget for accessories. Some brands of mitre saws come with accessories such as special workbenches or stands, which will increase your wholesale budget.

Chop saws are relatively inexpensive, so if you have a limited budget, you can try starting a wholesale chop saw business first. Its simple structure allows it to be placed directly on a flat surface for metal cutting and other operations without the need for other special supports or auxiliary accessories. Chop saws are also robustly designed, suitable for various heavy metal processing environments, and have a long service life with no additional maintenance costs.

Conclusion

This article introduces the differences between mitre saw and chop saw from five aspects. We found that mitre saw emphasizes the precision and flexibility of cutting, while chop saw pursues the rapid cutting of hard materials such as metal. If you would like to inquire about the details of other products, or if you would like to read new product blog, please feel free to contact us to discuss them together.

If you’ re interested in wholesaling either of these power saws, check out FIXTEC Brand. We offer a wide range of power saws, including mitre saws and chop saws, in various sizes for you to choose from. Our mitre saw features laser cutting, built-in LED light, extension bars, and a dust bag design, ensuring your precision cutting is fully guaranteed. Our chop saws come in various power ratings, easily cutting hard materials such as metal, pipe, and stone. Choose us as your power saws supplier, and we can provide free promotional materials, such as saw operation videos, e-manuals, clear images, and posters. We can also provide branded display racks, tool feather banners, T-shirts, caps, and other free gifts to promote your store, helping you attract customers and build repeat business.